Information:

Information:

Country: Taiwan

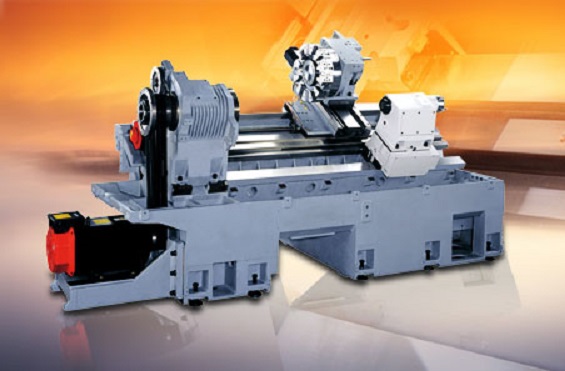

Manufacturer: GOODWAY MACHINE CORP.

Group: Lathe

Control System: Fanuc

Web site: http://www.goodwaycnc.com

Suppliers in your country: Suppliers

Additional Information: With tailstock or SUB-SPINDEL

Y and Cf-axies, driven tool

Technical specifications:

| CAPACITY |

GS-200 / L |

GS-260 / L |

GS-280 / L |

|

| Max. swing diameter |

Ø 470 mm |

|||

| Swing over saddle |

Ø 620 mm |

|||

| Max. turning diameter *1 |

Ø 420 mm |

|||

| Standard turning diameter *1 |

Ø 203 mm ( 8″ ) |

Ø 254 mm ( 10″ ) |

||

| Max. turning length *1 |

600 mm / 1,200 mm |

|||

| Max. weight load *2 |

170 kg |

230 kg |

250 kg |

|

| Chuck size *3 |

Ø 8″ |

Ø 10″ |

Ø 10″*4 |

|

| Bar capacity |

Ø 51 mm |

Ø 65 mm |

Ø 75 mm*4 |

|

| SPINDLE |

GS-200 / L |

GS-260 / L |

GS-280 / L |

|

| Hole through draw tube |

Ø 52 mm |

Ø 66 mm |

Ø 75.5 mm |

|

| Hole through spindle |

Ø 66 mm |

Ø 76 mm |

Ø 90 mm |

|

| Spindle bearing diameter |

Ø 100 mm |

Ø 120 mm |

Ø 130 mm |

|

| Hydraulic cylinder |

8″ |

10″ |

10″*4 |

|

| Spindle nose |

A2-6 |

A2-8 |

A2-8 |

|

| Spindle motor type |

FANUC β22 / 6,000 i ( AC / Wide-Range / Cont. Ouptut ) |

|||

| Motor output ( Cont. ) |

11 kW ( 15 HP ) |

|||

| Motor output ( 30min. / Peak ) |

15 kW / 18.5 kW ( 20 HP / 25 HP ) |

|||

| Motor full output speed |

750 rpm |

|||

| Spindle drive system |

Direct Belt Drive |

|||

| Spindle drive ratio |

4 : 5 |

2 : 3 |

7 : 12 |

|

| Spindle speed range |

48 ~ 4,800 rpm |

40 ~ 4,000 rpm |

35 ~ 3,500 rpm |

|

| Spindle full output speed |

600 rpm |

500 rpm |

440 rpm |

|

| Spindle torque ( 30 min.) |

239 N-m |

287 N-m |

327 N-m |

|

| Spindle torque ( Peak ) |

291 N-m |

350 N-m |

399 N-m |

|

| 2-SPEED SPINDLE ( OPTIONAL ) | ||||

| Spindle speed ranges |

L |

20 ~ 1,200 rpm |

20 ~ 1,000 rpm |

20 ~ 875 rpm |

|

H |

1,201 ~ 4,800 rpm |

1,001 ~ 4,000 rpm |

876 ~ 3,500 rpm |

|

| Spindle full output speed |

L |

400 rpm |

335 rpm |

295 rpm |

|

H |

600 rpm |

500 rpm |

440 rpm |

|

| Spindle torque ( 15 min. ) |

L |

358 N-m |

429 N-m |

490 N-m |

| Spindle torque ( 30 min. ) |

H |

239 N-m |

287 N-m |

327 N-m |

| Cf-AXIS SPINDLE ( OPTIONAL ) | ||||

| Cf-axis drive motor |

AC 0.75 kW ( 1HP FANUC α2 / 5,000i , Absolute encoder, 1,000,000/rev. ) |

|||

| Cf-axis drive ratio |

1 : 120 |

|||

| Cf-axis rapid |

33 rpm |

|||

| Cf-axis torque output ( Cont. ) |

Direct Belt Drive |

|||

| Min. spindle indexing angle |

± 0.001˚ |

|||

| Dynamic accuracy |

± 0.002˚ |

|||

| X & Z AXES |

GS-200 / L |

GS-260 / L |

GS-280 / L |

|

| Max. X-axis travel*1 |

+10 mm, – 200 mm, – 30 mm |

|||

| Max. Z-axis travel*1 |

+ 30 mm, – 570 mm |

|||

| X / Z axes rapids |

20 m/min. , 24 m/min. |

|||

| Slide way type |

Hardened & Ground Box Ways |

|||

| Feed rates |

1 ~ 4,800 mm/min. |

|||

| X-axis servo motor |

AC 1.6 kW ( 2.2 HP, FANUC α12 / 4,000is, Absolute encoder, 1,000,000 / rev. ) |

|||

| Z-axis servo motor |

AC 3.0 kW ( 4.1 HP, FANUC α12 / 3,000i , Absolute encoder, 1,000,000 / rev. ) |

|||

| X-axis ball screw Ø / pitch |

Ø 32 mm / Pitch 6 |

|||

| Z-axis ball screw Ø / pitch |

Ø 36 mm / Pitch 10 |

|||

| X / Z axes thrust ( Cont. ) |

961.8 kgf / 769.4 kgf |

|||

| TURRET |

GS-200 / L |

GS-260 / L |

GS-280 / L |

|

| Stations |

12 Standard |

|||

| Indexing drive |

FANUC AC Servo motor |

|||

| Indexing speed |

0.2 sec. Adjacent / 0.5 sec. 180 degrees ( Single step ) |

|||

| Accuracy |

Positioning: ± 0.00069°, Repeatability: ± 0.00027° |

|||

| OD tool shank size |

□ 25 mm |

|||

| ID tool shank size |

Ø 40 mm |

|||

| LIVE TOOLING TURRET ( OPTIONAL ) |

GS-200 / L |

GS-260 / L |

GS-280 / L |

|

| Max. turning length*1 |

600 mm / 1,200 mm |

595 mm / 1,195 mm |

||

| Stations |

12 |

|||

| Live tooling stations |

12 ( Live tooling tools rotate in working position only. ) |

|||

| Live tooling drive motor |

AC 3.0 kW ( 4.1 HP, FANUC α12/3,000i, Absolute encoder, 1,000,000 / rev.) |

|||

| Live tooling torque |

12 N-m ( Cont. ) / 34 N-m ( Intermittent ) |

|||

| Indexing drive type |

FANUC AC Servo motor |

|||

| Index speed |

0.2 sec. Adjacent / 0.5 sec. 180 degrees ( Single step ) |

|||

| OD tool shank size |

□ 25 mm |

|||

| ID tool shank size |

Ø 40 mm |

|||

| Live tooling shank size |

1 ~ 20 mm ER 32 collets |

|||

| Live tooling rpm range |

10 ~ 3,000 rpm |

|||

| Y-AXIS ( OPTIONAL ) |

GS-200 / L |

GS-260 / L |

GS-280 / L |

|

| Max. turning diameter |

Ø 340 mm |

|||

| Max. X-axis travel*1 |

+ 10 mm, – 160 mm, – 100 mm |

|||

| Max. Y-axis travel*1 |

120 mm = + 65 mm / – 55 mm |

|||

| X / Y axes rapids |

20 m/min. / 10 m/min. |

|||

| Slide way type |

Hardened & Ground Box Ways |

|||

| Feed rates |

1 ~ 4,800 mm/min. |

|||

| X-axis servo motor |

AC 1.6 kW ( 2.2 HP, FANUC α12/4,000is, Absolute encoder, 1,000,000 / rev. ) |

|||

| Y-axis servo motor |

AC 1.6 kW ( 2.2 HP, FANUC α8/3,000i, Absolute encoder, 1,000,000 / rev. ) |

|||

| X-axis ball screw Ø / pitch |

Ø 36 mm / Pitch 8 |

|||

| Y-axis ball screw Ø / pitch |

Ø 32 mm / Pitch 6 |

|||

| X / Y axes thrust ( Cont. ) |

961.8 kgf / 854.9 kgf |

|||

| SUB-SPINDEL ( OPTIONAL ) |

GS-200 / L |

GS-260 / L |

GS-280 / L |

|

| Standard turning diameter |

Ø 152 mm |

|||

| Max. turning length*¹ |

600 mm / 1,200 mm |

|||

| Chuck size*² |

Ø 6″ |

|||

| Hole through spindle |

Ø 46 mm |

|||

| Spindle bearing diameter |

Ø 80 mm |

|||

| Hydraulic cylinder |

6″ |

|||

| Spindle nose |

A2-5 |

|||

| Spindle motor type |

FANUC α112M / 15,000 iB ( AC / Wide-range / Cont. Output ) |

|||

| Motor output ( Cont. ) |

5.5 kW ( 7.5 HP ) |

|||

| Motor output ( 30 min. / Peak ) |

7.5 kW / 11 kW ( 10 HP / 15 HP ) |

|||

| Motor full output speed |

1,500 rpm |

|||

| Spindle drive system |

Direct built-in motor ( Integrated Motor ) |

|||

| Spindle drive ratio |

1 : 1 |

|||

| Spindle speed range |

60 ~ 6,000 rpm |

|||

| Spindle full output speed |

1,500 rpm |

|||

| Spindle torque (30min.) |

48 N-m |

|||

| Spindle torque (Peak) |

55 N-m |

|||

| B-axis travel*¹ |

+ 30 mm, – 570 mm |

|||

| B-axis rapid |

24 m/min. |

|||

| Slide way type |

Hardened & Ground Box Ways |

|||

| B-axis servo motor |

AC 3.0 kW ( 4.1 HP, FANUC α12 / 3,000i, Absolute encoder, 1,000,000 / rev. ) |

|||

| B-axis ball screw Ø / pitch |

Ø 36 mm / Pitch 10 |

|||

| B-axis thrust ( Cont. ) |

769.4 kgf |

|||

| TAILSTOCK ( OPTIONAL ) |

GS-200 / L |

GS-260 / L |

GS-280 / L |

|

| Quill center taper |

MT#3 ( Built-in spindle type, Live quill ) |

|||

| Quill diameter / travel |

Ø 85 mm / 120 mm |

|||

| Tail stock base travel*¹ |

470 mm / 1,070 mm |

|||

| Programmable quill / base |

Yes / Yes |

|||

| Programmable base type |

Positioned by Z-axis carriage through user-friendly macro programming |

|||

| MAIN SPINDEL PARTS CATCHER ( OPTIONAL ) | ||||

| Maximum part diameter |

Ø 60 mm |

|||

| Maximum part length |

180 mm |

|||

| Maximum part weight |

4 kg |

|||

| GENERAL |

GS-200 / L |

GS-260 / L |

GS-280 / L |

|

| Positioning accuracy ( X / Y / Z / B ) |

± 0.005 mm |

|||

| Repeatability ( X / Y / Z / B ) |

± 0.003 mm |

|||

| Voltage / Power requirement |

AC 200 / 220 +10% to -15% 3 phase / 26 KVA |

|||

| Hydraulic tank capacity |

40 L |

|||

| Coolant tank capacity |

200 L |

|||

| Coolant pump |

0.5 kW ( 3/4 HP, 60Hz ) rated at 4.2 bar ( 60 PSI ) |

|||

| Machine weight |

4,800 / 5,600 kg |

|||

| Machine weight ( MS models ) |

5,000 / 5,800 kg |

|||

| Dimensions L × W × H*1 |

Machine : 2,670 / 3,500 x 1,955 x 1,890 mm |

|||

|

Machine w / Y-axis : 2,670 / 3,500 x 1,920 x 2,260 mm |

||||

| Control | ||||

| FANUC Oi-TD | ||||

| Specifications are subject to change without notice. *1 Individual models may vary, please see interference drawings. *2 Work piece supported by chuck & tailstock. *3 Chucks optional. *4 Optional 10″ Big-bore hydraulic cylinder & chuck provide Ø 78 mm bar capacity. |

||||